Achromatic Lenses

Achromats can come in various shapes and sizes and serve a wide variety of practical applications, such as correcting chromatic aberrations. LaCroix Precision Optics has specialized in manufacturing and assembling thousands of achromatic lenses every week, including triplets and aspheric achromats.

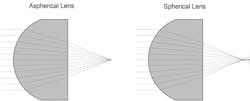

Standard Lens

Achromatic Doublet

The process of creating achromatic lenses starts with a quote generated by a Manufacturing Engineer. The right optical glass material is then ordered and sent to the production line. While in production, the crown and flint lenses are manufactured separately in a typical fashion. The crown is convex and is made using lower-dispersion material while the flint is typically concave and utilizes relatively higher dispersion material. Once we manufacture the various lenses, they are aligned in both the optical and mechanical axis and cemented together using a specialized index-specific optical cement. The optical cement is then cured using UV light. After assembly, some of the doublets are centered to the final diameter while others are pre-centered before cementing. Doublets can also be blackened after assembly to reduce scattering, which can be beneficial in some optical applications.

LaCroix Manufacturing Engineers will work with our Production Technicians to optimize the manufacturing process to utilize a combination of CNC and conventional manufacturing methods. Special proprietary alignment devices are used to ensure the optical axis of the different elements can be maintained to within seconds.

Our other capabilities include:

- Precision centering

- Custom truncations

- Off-axis spherical lenses

Coatings

We have extensive in-house coating capabilities to meet your requirements. See our coating capabilities.

Uses for Achromats

- Surgical loupes

- Microscopy

- Multi-spectral imaging

- Telescopes

- LASIK devices

- Machine vision

- Ophthalmology

- Threat detection

- Laser target designators